Brushless DC (BLDC) Motor Family

NT DYNAMO® Brushless DC (BLDC) Geared Specifications:

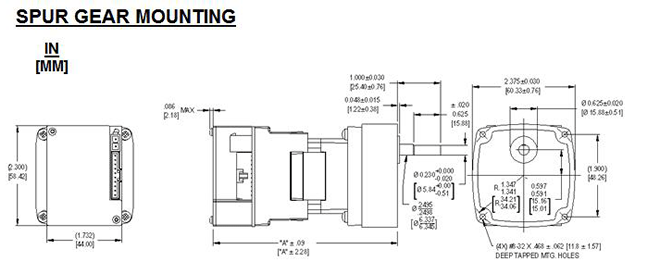

| Spur |

Click to Enlarge |

Up to 600:1 Gear Ratio

Up to 200 oz-in [1412 mN-m] of Torque

AGMA 7 Gear Quality

|

| |

|

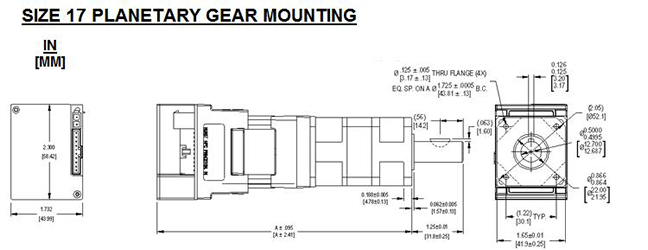

| Planetary |

|

Click to Enlarge |

Wide Selection of Gear Ratios and Features

Inline, Right Angle, and Metric

High Torque and Low Backlash

|

| |

|

| Some factors to consider in maximizing your

application system’s performance: |

| |

|

- Torque Multiplication

- Radial Loading

- Noise

|

- Speed Reduction

- Axial Loading

- Inertia Matching

|

Spur

gearheads will suit most needs in relatively low-torque

applications. However, spur configurations have higher

backlash and are usually less efficient than planetary types

of similar construction. For constant velocity and

unidirectional applications where backlash is less of a

concern, spur gearheads are ideal.

Planetary

gearheads are generally specified for their high rated

torque and high input speed. Planetary gearheads are more

robust with higher accuracy, lower backlash, and longer life

than spur gearheads. They are well suited for higher load

applications in small packages ranging from nut runners and

nut setters to small medical tools, pumps, and other

devices.

The gearhead solution (Spur Vs. Planetary)

is primarily dependent upon the application. Some factors to

be considered in making proper trade-offs between cost and

performance are shown below.

|

|

DESIGN FACTORS

|

GEARHEAD TYPE

|

|

SPUR

|

PLANETARY

|

|

Torque Capacity

|

Lower

|

Higher |

|

Power to Weight Ratio |

Lower |

Higher |

|

Power to Size Ratio |

Lower |

Higher |

|

Torsional Stiffness |

Lower |

Higher |

| Backlash |

Higher |

Lower |

|

Available Number of Gear Ratios |

Higher |

Lower |

|

Operating Speed |

Lower |

Higher |

| Size |

Larger |

Smaller |

| Cost |

Lower |

Higher |

|

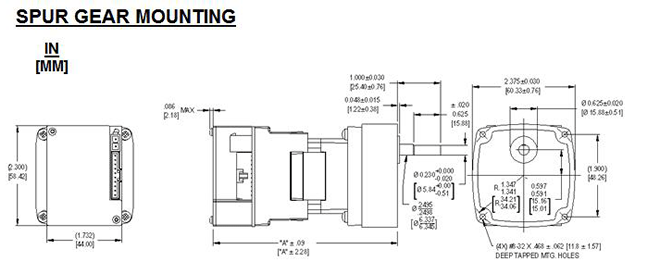

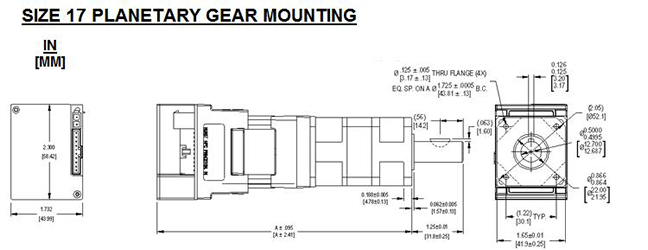

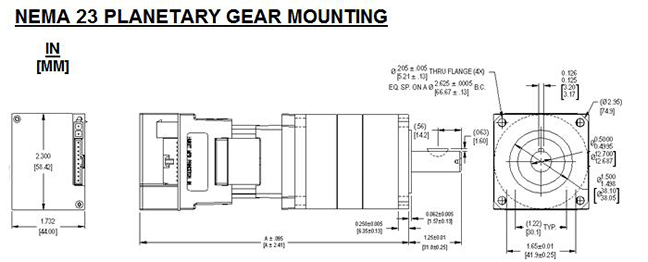

NT DYNAMO® Brushless DC (BLDC) Geared Diagrams:

|

|

Model

|

Overall Length (A) in [mm]

|

|

0

|

4.87 [123.7]

|

|

6

|

7.12 [180.8]

|

|

|

|

Model

|

Overall Length (A) in [mm]

|

|

Model

|

Overall Length (A) in [mm]

|

|

0

|

6.49 [164.8]

|

4

|

8.74 [222.0]

|

|

0*

|

6.98 [177.3]

|

4*

|

9.23 [234.4]

|

|

* Gear Reductions 16:1 and higher

|

|

|

|

Model

|

Overall Length (A) in [mm]

|

|

Model

|

Overall Length (A) in [mm]

|

|

0

|

6.68 [169.7]

|

4

|

8.93 [226.8]

|

|

0*

|

7.50 [190.5]

|

4*

|

9.75 [247.7]

|

|

* Gear Reductions 16:1 and higher |

|

NT DYNAMO® Brushless DC (BLDC) Geared Part Number Specification:

Spur Gearing Part Number Identification Matrix

| Rated Speed |

Rated Torque @ 24Vdc |

Rated Current @ 24Vdc |

Gear Ratio |

Gear Stages |

Max. Radial Load |

Max. Axial Load |

Wt. |

Length “A” inches [mm] |

Part Number |

| RPM |

(oz.in.) |

(Amps) |

|

|

(lb) |

(lb) |

(lb) |

ValuDrive® Control |

Model # |

Winding |

Gear # |

| 93 to 280 |

15 |

0.35 |

2:1 |

2 |

7 |

5 |

1.6 |

4.87 [123.7] |

0 |

E |

G00 |

| 75 |

1.4 |

2.9 |

7.12 [180.8] |

6 |

E |

G00 |

| 37 to 112 |

38 |

0.35 |

5:1 |

2 |

7 |

5 |

1.6 |

4.87 [123.7] |

0 |

E |

G01 |

| 188 |

1.4 |

2.9 |

7.12 [180.8] |

6 |

E |

G01 |

| 18 to 56 |

75 |

0.35 |

10:1 |

2 |

7 |

5 |

1.6 |

4.87 [123.7] |

0 |

E |

G02 |

| 2001 |

1.4 |

2.9 |

7.12 [180.8] |

6 |

E |

G02 |

| 6.2 to 18 |

2001 |

0.35 |

30:1 |

3 |

7 |

5 |

1.6 |

4.87 [123.7] |

0 |

E |

G03 |

| 3.1 to 9.3 |

2001 |

0.35 |

60:1 |

3 |

7 |

5 |

1.6 |

4.87 [123.7] |

0 |

E |

G04 |

| 1.8 to 5.6 |

2001 |

0.35 |

100:1 |

4 |

7 |

5 |

1.6 |

4.87 [123.7] |

0 |

E |

G05 |

| 0.6 to 1.8 |

2001 |

0.35 |

300:1 |

5 |

7 |

5 |

1.6 |

4.87 [123.7] |

0 |

E |

G06 |

| 0.3 to 0.9 |

2001 |

0.35 |

600:1 |

5 |

7 |

5 |

1.6 |

4.87 [123.7] |

0 |

E |

G07 |

1Motor rated torque will exceed the 200 oz.in. [1412 mN-m] maximum geartrain rating.

If this service is anticipated, a current limiting device should be used.

- All values are at nominal rated input voltage.

- Ambient operating temperature range: 0 to 40°C.

- At 25°C ambient the max motor winding operating temperature rise is 65°C with gearmotor mounted to a

4" x 4" x 0.25" aluminum plate.

- Performance data shown is typical. More detailed data is available from Hurst for each of the above ratings.

- Refer to the Customer Data Sheet supplied with your system or contact Hurst for other gear ratios and voltages (7 to 45 Vdc).

|

|

Planetary Gearing Part Number Identification Matrix

|

Rated Speed |

Rated Torque @ 24Vdc |

Rated Current @ 24Vdc |

Gear Ratio |

Gear Stage |

Gear Head Inertia |

Gear Head Backlash (Std./Low) |

Wt. |

Length “A” inches [mm] |

Part Number |

|

RPM |

lb.in. |

Amps |

|

|

oz.in.-sec2 |

arc-min |

lb. |

ValuDrive® Control |

Model # |

Winding |

Gear # |

Size

17 |

225 to 675 |

1.7 |

1 |

3:1 |

Single |

3.83E-04 |

6/3 |

2.1 |

6.49 [164.8] |

2 |

C |

P10 |

| 6.8 |

3.6 |

3:1 |

Single |

3.83E-04 |

6/3 |

3.4 |

8.74 [222.0] |

4 |

C |

P10 |

| 168 to 506 |

2.3 |

1 |

4:1 |

Single |

2.41E-04 |

6/3 |

2.1 |

6.49 [164.8] |

2 |

C |

P11 |

| 9 |

3.6 |

4:1 |

Single |

2.41E-04 |

6/3 |

3.4 |

8.74 [222.0] |

4 |

C |

P11 |

| 122 to 368 |

3.1 |

1 |

5.5:1 |

Single |

1.76E-04 |

6/3 |

2.1 |

6.49 [164.8] |

2 |

C |

P12 |

| 12 |

3.6 |

5.5:1 |

Single |

1.76E-04 |

6/3 |

3.4 |

8.74 [222.0] |

4 |

C |

P12 |

| 96 to 289 |

3.9 |

1 |

7:1 |

Single |

1.51E-04 |

6/3 |

2.1 |

6.49 [164.8] |

2 |

C |

P13 |

| 16 |

3.6 |

7:1 |

Single |

1.51E-04 |

6/3 |

3.4 |

8.74 [222.0] |

4 |

C |

P13 |

| 67 to 202 |

5.6 |

1 |

10:1 |

Single |

1.54E-04 |

6/3 |

2.1 |

6.49 [164.8] |

2 |

C |

P14 |

| 23 |

3.6 |

10:1 |

Single |

1.54E-04 |

6/3 |

3.4 |

8.74 [222.0] |

4 |

C |

P14 |

| 42 to 127 |

8.5 |

1 |

16:1 |

Double |

2.22E-04 |

10/5 |

2.7 |

6.98 [177.3] |

2 |

C |

P15 |

| 34 |

3.6 |

16:1 |

Double |

2.22E-04 |

10/5 |

4 |

9.23 [234.4] |

4 |

C |

P15 |

| 31 to 92 |

12 |

1 |

22:1 |

Double |

1.73E-04 |

10/5 |

2.7 |

6.98 [177.3] |

2 |

C |

P16 |

| 47 |

3.6 |

22:1 |

Double |

1.73E-04 |

10/5 |

4 |

9.23 [234.4] |

4 |

C |

P16 |

| 24 to 72 |

15 |

1 |

28:1 |

Double |

1.50E-04 |

10/5 |

2.7 |

6.98 [177.3] |

2 |

C |

P17 |

| 60 |

3.6 |

28:1 |

Double |

1.50E-04 |

10/5 |

4 |

9.23 [234.4] |

4 |

C |

P17 |

| 17 to 51 |

21 |

1 |

40:1 |

Double |

1.32E-04 |

10/5 |

2.7 |

6.98 [177.3] |

2 |

C |

P18 |

| 85 |

3.6 |

40:1 |

Double |

1.32E-04 |

10/5 |

4 |

9.23 [234.4] |

4 |

C |

P18 |

| 12 to 37 |

29 |

1 |

55:1 |

Double |

1.31E-04 |

10/5 |

2.7 |

6.98 [177.3] |

2 |

C |

P1A |

| 1171 |

3.6 |

55:1 |

Double |

1.31E-04 |

10/5 |

4 |

9.23 [234.4] |

4 |

C |

P1A |

| 10 to 29 |

37 |

1 |

70:1 |

Double |

1.30E-04 |

10/5 |

2.7 |

6.98 [177.3] |

2 |

C |

P1B |

| 1491 |

3.6 |

70:1 |

Double |

1.30E-04 |

10/5 |

4 |

9.23 [234.4] |

4 |

C |

P1B |

| 6.7 to 20 |

521 |

1 |

100:1 |

Double |

1.30E-04 |

10/5 |

2.7 |

6.98 [177.3] |

2 |

C |

P1C |

|

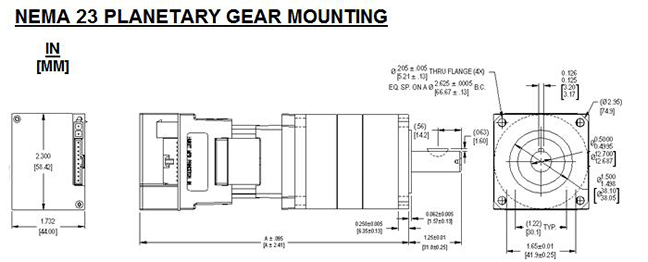

NEMA

23 |

225 to 675 |

1.7 |

1 |

3:1 |

Single |

1.68E-03 |

6/3 |

3.2 |

6.68 [169.7] |

2 |

C |

P20 |

| 6.8 |

3.6 |

3:1 |

Single |

1.68E-03 |

6/3 |

4.5 |

8.93 [226.8] |

4 |

C |

P20 |

| 168 to 506 |

2.3 |

1 |

4:1 |

Single |

1.27E-03 |

6/3 |

3.2 |

6.68 [169.7] |

2 |

C |

P21 |

| 9 |

3.6 |

4:1 |

Single |

1.27E-03 |

6/3 |

4.5 |

8.93 [226.8] |

4 |

C |

P21 |

| 122 to 368 |

3.1 |

1 |

5.5:1 |

Single |

1.08E-03 |

6/3 |

3.2 |

6.68 [169.7] |

2 |

C |

P22 |

| 12 |

3.6 |

5.5:1 |

Single |

1.08E-03 |

6/3 |

4.5 |

8.93 [226.8] |

4 |

C |

P22 |

| 96 to 289 |

3.9 |

1 |

7:1 |

Single |

1.01E-03 |

6/3 |

3.2 |

6.68 [169.7] |

2 |

C |

P23 |

| 16 |

3.6 |

7:1 |

Single |

1.01E-03 |

6/3 |

4.5 |

8.93 [226.8] |

4 |

C |

P23 |

| 67 to 202 |

5.6 |

1 |

10:1 |

Single |

9.50E-04 |

6/3 |

3.2 |

6.68 [169.7] |

2 |

C |

P24 |

| 23 |

3.6 |

10:1 |

Single |

9.50E-04 |

6/3 |

4.5 |

8.93 [226.8] |

4 |

C |

P24 |

| 42 to 127 |

8.5 |

1 |

16:1 |

Double |

1.28E-03 |

10/5 |

4.2 |

7.50 [190.5] |

2 |

C |

P25 |

| 34 |

3.6 |

16:1 |

Double |

1.28E-03 |

10/5 |

5.5 |

9.75 [247.7] |

4 |

C |

P25 |

| 31 to 92 |

12 |

1 |

22:1 |

Double |

1.09E-03 |

10/5 |

4.2 |

7.50 [190.5] |

2 |

C |

P26 |

| 47 |

3.6 |

22:1 |

Double |

1.09E-03 |

10/5 |

5.5 |

9.75 [247.7] |

4 |

C |

P26 |

| 24 to 72 |

15 |

1 |

28:1 |

Double |

1.01E-03 |

10/5 |

4.2 |

7.50 [190.5] |

2 |

C |

P27 |

| 60 |

3.6 |

28:1 |

Double |

1.01E-03 |

10/5 |

5.5 |

9.75 [247.7] |

4 |

C |

P27 |

| 17 to 51 |

21 |

1 |

40:1 |

Double |

9.53E-04 |

10/5 |

4.2 |

7.50 [190.5] |

2 |

C |

P28 |

| 85 |

3.6 |

40:1 |

Double |

9.53E-04 |

10/5 |

5.5 |

9.75 [247.7] |

4 |

C |

P28 |

| 12 to 37 |

29 |

1 |

55:1 |

Double |

9.51E-04 |

10/5 |

4.2 |

7.50 [190.5] |

2 |

C |

P2A |

| 1171 |

3.6 |

55:1 |

Double |

9.51E-04 |

10/5 |

5.5 |

9.75 [247.7] |

4 |

C |

P2A |

| 10 to 29 |

37 |

1 |

70:1 |

Double |

9.50E-04 |

10/5 |

4.2 |

7.50 [190.5] |

2 |

C |

P2B |

| 1491 |

3.6 |

70:1 |

Double |

9.50E-04 |

10/5 |

5.5 |

9.75 [247.7] |

4 |

C |

P2B |

| 6.7 to 20 |

521 |

1 |

100:1 |

Double |

9.49E-04 |

10/5 |

4.2 |

7.50 [190.5] |

2 |

C |

P2C |

1Motor rated torque can exceed indicated maximum gearhead rating. If this service is anticipated, a current limiting

device should be used.

- All values are at nominal rated input voltage.

- Ambient operating temperature range: 0 to 40°C.

- At 25°C ambient the max motor winding operating temperature rise is 65°C with gearmotor mounted to a

4" x 4" x 0.25" aluminum plate.

- Performance data shown is typical. More detailed data is available from Hurst for each of the above ratings.

- Refer to the Customer Data Sheet supplied with your system or contact Hurst for other gear ratios and voltages (7 to 45 Vdc).

|

|

Dynamo Part Number Identification Matrix

|

|

Product Family

|

Operating Mode

|

Control Method (Input Signal)

|

Encoder (ppr)

|

Thermal Protection

|

Model -

Rated Torque (oz-inch)

|

Input Voltage (Vdc)

|

Winding (See Chart)

|

Mechanical Features

|

Preset Speed10 (RPM)

|

|

DM - Dynamo

|

A – External1

|

0 – None

|

0 - None

|

0 - None

|

0 – See Note 11

|

012 – 12 V

|

A

|

100 - Size 17 without cables

|

0 - None

|

|

|

B - Open Loop Speed

|

1 – Analog3

|

1 - 100 ppr

|

|

1 - 5

|

024 – 24 V

|

B

|

101 - Size 17 with cables

|

1 - Special13

|

|

|

C - Closed Loop Speed

|

2 – Analog4(w/ 5Vdc supply)

|

2 - 250 ppr

|

|

2 - 10

|

036 – 36 V

|

C

|

200 - NEMA 23 without cables

|

A – 250

|

|

|

D – Preset Speed2

|

3 – PWM3,5

|

3 - 400 ppr

|

|

3 - 20

|

045 – 45 V

|

D

|

201 - NEMA 23 with cables

|

B – 300

|

|

|

E – Torque12 (Open Loop)

|

4 – PWM5

(w/ 5Vdc supply)

|

4 - 1000 ppr

|

|

4 - 30

|

048 – 48 V

|

E

|

G00-079 Spur Gear Ratios with cables

|

C – 500

|

|

|

|

5 – PWM & Direction3,6

|

5 - 256 ppr (w/index)7

|

|

5 - 40

|

|

|

P10-P1C9 Planetary Gear Ratios (Size 17) with cables

|

D – 600

|

|

|

|

6 - PWM & Direction6

(w/ 5Vdc supply)

|

|

|

6 - See Note11

|

|

|

P20-P2C9 Planetary Gear Ratios (NEMA 23) with cables

|

E – 750

|

|

|

|

7 - ON / OFF3

|

|

|

|

|

|

|

F – 900

|

|

|

|

8 ON / OFF4

|

|

|

|

|

|

|

G – 1000

|

|

|

|

|

|

|

|

|

|

|

H – 1200

|

|

|

|

|

|

|

|

|

|

|

J – 1500

|

|

|

|

|

|

|

|

|

|

|

K – 1800

|

|

|

|

|

|

|

|

|

|

|

L - 2000

|

|

|

|

|

|

|

|

|

|

|

M – 2500

|

|

|

|

|

|

|

|

|

|

|

N – 3000

|

|

|

|

|

|

|

|

|

|

|

P – 3500

|

|

|

|

|

|

|

|

|

|

|

Q – 3600

|

|

|

|

|

|

|

|

|

|

|

R – 4000

|

|

|

|

|

|

|

|

|

|

|

S - 4500

|

1Only Motor phase and commutation signal outputs are supplied. (User supplies their own motor drive).

2Use only with Control Method

7 – ON/OFF

or8 – ON/OFF.

3

User to supply 5 Vdc control logic signal; Power supply able to supply a typical current of 35 mA.

4

Internally supplied 5 Vdc source; max current = 5 mA.

5

PWM input signal used in conjunction with direction line (Pin 7).

6

PWM input signal (Pin 3) used as command and direction.

7

Only available with Operating Mode A– External.

8

Use only with Operating Mode A – External or 45 Vdc for all other

operating modes.

9

See Dynamo Spur Gearing part number Identification Matrix or Dynamo Planetary Gearing part number Identification Matrix for

Gear Options.

10

Use only with Operating Mode D - Preset Speed.

Preset Speed must be below solid portion of the diagonal line of the winding curve

selected. The

maximum continuous torque is dependent upon the preset speed selected. Other Preset speeds available upon

request.

11

Use only with Spur and Planetary Gearing; See Dynamo Spur Gearing part number Identification Matrix

or Dynamo Planetary Gearing

part number Identification Matrix for Gear Options.

12

Use only with 1 – Analog

or 2 – Analog (w/ 5Vdc supply).

13

If standard listed speeds do not meet your needs, contact the factory for your specific requests.

|

|

Motor Only Curves

|

NT DYNAMO

® Brushless DC (BLDC) Geared Model Table:

(Note: For Features Or Speeds Not Listed In Table, Contact Factory)

|

DMA0100024EG030 |

Spur |

200 |

1412.3 |

30 |

Feedback |

See diagram |

100 line |

24 |

.1 |

.35 |

6.2 to 18 |

28 |

20.3 |

27.2 |

771 |

Contact

Factory

|

DMA0100024EG040 |

Spur |

200 |

1412.3 |

60 |

Feedback |

See diagram |

100 line |

24 |

.1 |

.35 |

3.1 to 9.3 |

28 |

20.3 |

27.2 |

771 |

Contact

Factory |

DMA0100024EG050 |

Spur |

200 |

1412.3 |

100 |

Feedback |

See diagram |

100 line |

24 |

.1 |

.35 |

1.8 to 5.6 |

28 |

20.3 |

27.2 |

771 |

Contact

Factory |

DMA0106024EG000 |

Spur |

75 |

529.6 |

2 |

Feedback |

See diagram |

100 line |

24 |

.2 |

1.4 |

93 to 280 |

4 |

4.1 |

27.2 |

771 |

Contact

Factory |

DMA0106024EG010 |

Spur |

188 |

1327.6 |

5 |

Feedback |

See diagram |

100 line |

24 |

.2 |

1.4 |

37 to 112 |

4 |

4.1 |

27.2 |

771 |

Contact

Factory |

DMA0106024EG020 |

Spur |

200 |

1412.3 |

10 |

Feedback |

See diagram |

100 line |

24 |

.2 |

1.4 |

18 to 56 |

4 |

4.1 |

27.2 |

771 |

Contact

Factory |

DMA0104024CP100 |

Planetary |

108.8 |

768.3 |

3 |

Feedback |

Size 17 |

100 line |

24 |

.6 |

3.6 |

225 to 675 |

.83 |

1.02 |

27.2 |

771 |

Contact

Factory |

DMA0104024CP120 |

Planetary |

192 |

1355.8 |

5.5 |

Feedback |

Size 17 |

100 line |

24 |

.6 |

3.6 |

122 to 368 |

.83 |

1.02 |

27.2 |

771 |

Contact

Factory |

DMA0104024CP140 |

Planetary |

368 |

2598.7 |

10 |

Feedback |

Size 17 |

100 line |

24 |

.6 |

3.6 |

67 to 202 |

.83 |

1.02 |

27.2 |

771 |

Contact

Factory |

DMA0104024CP200 |

Planetary |

108.8 |

768.3 |

3 |

Feedback |

NEMA 23 |

100 line |

24 |

.6 |

3.6 |

225 to 675 |

.83 |

1.02 |

35.2 |

998 |

Contact

Factory |

DMA0104024CP220 |

Planetary |

192 |

1355.8 |

5.5 |

Feedback |

NEMA 23 |

100 line |

24 |

.6 |

3.6 |

122 to 368 |

.83 |

1.02 |

35.2 |

998 |

Contact

Factory |

DMA0104024CP240 |

Planetary |

368 |

2598.7 |

10 |

Feedback |

NEMA 23 |

100 line |

24 |

.6 |

3.6 |

67 to 202 |

.83 |

1.02 |

35.2 |

998 |

|

DMB1100024EG030 |

Spur |

200 |

1412.3 |

30 |

Analog Open |

See diagram |

100 line |

24 |

.1 |

.35 |

6.2 to 18 |

28 |

20.3 |

27.2 |

771 |

Contact

Factory |

DMB1100024EG040 |

Spur |

200 |

1412.3 |

60 |

Analog Open |

See diagram |

100 line |

24 |

.1 |

.35 |

3.1 to 9.3 |

28 |

20.3 |

27.2 |

771 |

Contact

Factory |

DMB1100024EG050 |

Spur |

200 |

1412.3 |

100 |

Analog Open |

See diagram |

100 line |

24 |

.1 |

.35 |

1.8 to 5.6 |

28 |

20.3 |

27.2 |

771 |

Contact

Factory |

DMB1106024EG000 |

Spur |

75 |

529.6 |

2 |

Analog Open |

See diagram |

100 line |

24 |

.2 |

1.4 |

93 to 280 |

4 |

4.1 |

27.2 |

771 |

Contact

Factory |

DMB1106024EG010 |

Spur |

188 |

1327.6 |

5 |

Analog Open |

See diagram |

100 line |

24 |

.2 |

1.4 |

37 to 112 |

4 |

4.1 |

27.2 |

771 |

Contact

Factory |

DMB1106024EG020 |

Spur |

200 |

1412.3 |

10 |

Analog Open |

See diagram |

100 line |

24 |

.2 |

1.4 |

18 to 56 |

4 |

4.1 |

27.2 |

771 |

Contact

Factory |

DMB1104042CP100 |

Planetary |

108.8 |

768.3 |

3 |

Analog Open |

Size 17 |

100 line |

24 |

.6 |

3.6 |

225 to 675 |

.83 |

1.02 |

27.2 |

771 |

Contact

Factory |

DMB1104024CP120 |

Planetary |

192 |

1355.8 |

5.5 |

Analog Open |

Size 17 |

100 line |

24 |

.6 |

3.6 |

122 to 368 |

.83 |

1.02 |

27.2 |

771 |

Contact

Factory |

DMB1104024CP140 |

Planetary |

368 |

2598.7 |

10 |

Analog Open |

Size 17 |

100 line |

24 |

.6 |

3.6 |

67 to 202 |

.83 |

1.02 |

27.2 |

771 |

Contact

Factory |

DMB1104024CP200 |

Planetary |

108.8 |

768.3 |

3 |

Analog Open |

NEMA 23 |

100 line |

24 |

.6 |

3.6 |

225 to 675 |

.83 |

1.02 |

35.2 |

998 |

Contact

Factory |

DMB1104024CP220 |

Planetary |

192 |

1355.8 |

5.5 |

Analog Open |

NEMA 23 |

100 line |

24 |

.6 |

3.6 |

122 to 368 |

.83 |

1.02 |

35.2 |

998 |

Contact

Factory |

DMB1104024CP240 |

Planetary |

368 |

2598.7 |

10 |

Analog Open |

NEMA 23 |

100 line |

24 |

.6 |

3.6 |

67 to 202 |

.83 |

1.02 |

35.2 |

998 |

|

|

DMB2106024EG010 |

Spur |

188 |

1327.6 |

5 |

Analog Open |

See diagram |

100 line |

24 |

.2 |

1.4 |

37 to 112 |

4 |

4.1 |

27.2 |

771 |

Contact

Factory |

DMC2000024EG000 |

Spur |

15 |

105.9 |

2 |

Analog Closed |

See diagram |

None |

24 |

.1 |

.35 |

93 to 280 |

28 |

20.3 |

27.2 |

771 |