Permanent Magnet AC Synchronous Motor Family

Series A, AB Geared

Permanent Magnet AC Synchronous A, AB Geared Specifications:

| Torque Range: | Up to 150 oz-in [1059 mN-m] |

| Output Speed: | 1 to 600 RPM |

| Insulation Class: | Class A (105°C) |

| Lead Wire: | 4 leads 22AWG (approx. 9 inches [228.6 mm]) |

| Operation Ambient Temp: | -10°C to +40°C (approx.) |

| Gear Unit: | Zinc Die Cast - AGMA 7 Standard with hardened steel gears |

| Shaft Bearing: | Sleeve Bearing |

| E37163, Component Time Indicating and Recording

Appliances,

115Vac 60 Hz Standard Rotor |

|

| Card No. 42576, Motors and Generators, 115 Vac, 60 Hz, Standard Rotor, 3 watts max. |

|

| Capacitor is required for operation. Capacitor supplied with 115 Vac motors. | |

| Note: Typical data subject to change without notification | |

Addtional Information:

|

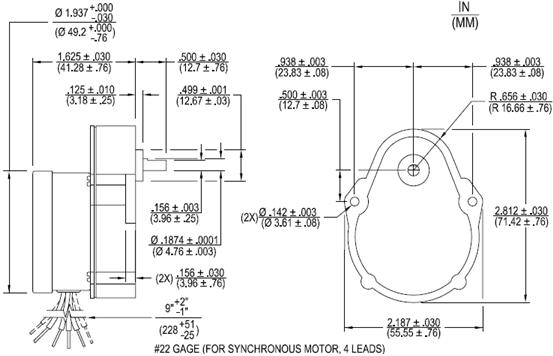

A, AB Geared Drawings:

Pear-Shaped Gear Mounting  |

A, AB Geared Diagrams:

|

|

Add to Cart |

Model |

Part Number |

Stock | Grainger SKU |

Rated Torque (oz-in) |

Rated Torque (mN-m) |

Reduction |

Output Speed (RPM) 60Hz |

Output Speed (RPM) 50Hz |

Input Power (watts) |

Voltage (Vac) 60Hz |

Voltage (Vac) 50Hz |

Capacitor Value (mfd) |

Weight (oz) |

Weight (grams) |

| AB | 3006-002 | Stock | 6A188 | 104.9 | 741 | 100 | 6 | -- | 5 | 115 | -- | .5 | 11.01 | 312 | |

| AB | 3006-004 | 6A189 | 87.9 | 621 | 60 | 10 | -- | 5 | 115 | -- | .5 | 11.01 | 312 | ||

| AB | 3006-005 | 6Z539 | 72.9 | 515 | 50 | 12 | -- | 5 | 115 | -- | .5 | 11.01 | 312 | ||

| AB | 3006-007 | Stock | 6Z540 | 44 | 311 | 30 | 20 | -- | 5 | 115 | -- | .5 | 11.01 | 312 | |

| AB | 3006-009 | 6A190 | 29 | 205 | 20 | 30 | -- | 5 | 115 | -- | .5 | 11.01 | 312 | ||

| AB | 3006-011 | 23.9 | 169 | 15 | 40 | -- | 5 | 115 | -- | .5 | 11.01 | 312 | |||

| AB | 3006-012 | 19 | 134 | 12 | 50 | -- | 5 | 115 | -- | .5 | 11.01 | 312 | |||

| AB | 3006-013 | Stock | 6Z541 | 16 | 113 | 10 | 60 | -- | 5 | 115 | -- | .5 | 11.01 | 312 | |

| AB | 3006-014 | 6Z542 | 7.9 | 56 | 5 | 120 | -- | 5 | 115 | -- | .5 | 11.01 | 312 | ||

| AB | 3006-016 | 5.4 | 38 | 3.5 | 180 | -- | 5 | 115 | -- | .5 | 11.01 | 312 | |||

| AB | 3006-017 | 4.8 | 34 | 3 | 200 | -- | 5 | 115 | -- | .5 | 11.01 | 312 | |||

| AB | 3006-019 | 3.3 | 23 | 2 | 300 | -- | 5 | 115 | -- | .5 | 11.01 | 312 | |||

| AB | 3006-026 | 16 | 113 | 8.5 | -- | 60 | 4 | -- | 115 | .5 | 11.01 | 312 | |||

| AB | 3006-027 | 7.9 | 56 | 4.17 | -- | 120 | 4 | -- | 115 | .5 | 11.01 | 312 | |||

| AB | 3006-0421 | 72.9 | 515 | 41.57 | -- | 12 | 4 | -- | 220 | .15 | 11.01 | 312 | |||

| AB | 3006-0651 | 44 | 311 | 30 | 20 | -- | 5 | 24 | -- | 10 | 11.01 | 312 | |||

| AB | 3006-0751 | 104.9 | 741 | 83.33 | -- | 6 | 4 | -- | 230 | .12 | 11.01 | 312 | |||

| AB | 3006-0811 | 104.9 | 741 | 83.33 | -- | 6 | 4 | -- | 220 | .15 | 11.01 | 312 | |||

| AB | 3006-0881 | 29 | 205 | 16.67 | -- | 30 | 4 | -- | 230 | .12 | 11.01 | 312 | |||

| AB | 3013-0072 | 71.9 | 508 | 30 | 20 | -- | 6.5 | 115 | -- | .62 | 11.01 | 312 | |||

| AB | 3013-0082 | 60 | 424 | 25 | 24 | -- | 6.5 | 115 | -- | .62 | 11.01 | 312 | |||

| AB | 3013-0092 | 48 | 339 | 20 | 30 | -- | 6.5 | 115 | -- | .62 | 11.01 | 312 | |||

| AB | 3013-012 | 31.4 | 222 | 12 | 50 | -- | 6.5 | 115 | -- | .62 | 11.01 | 312 | |||

| AB | 3013-014 | 13 | 92 | 5 | 120 | -- | 6.5 | 115 | -- | .62 | 11.01 | 312 | |||

| AB | 3013-017 | 7.8 | 55 | 3 | 200 | -- | 6.5 | 115 | -- | .62 | 11.01 | 312 | |||

| A | 3002-0231, 3 | 150 | 1059 | 900 | .33 | -- | 3 | 115 | -- | .25 | 11.01 | 312 | |||

| A | 3002-0883 | 150 | 1059 | 150 | .33 | -- | 3 | 24 | -- | 5.7 | 11.01 | 312 | |||

| A | 3002-0253 | 150 | 1059 | 600 | .5 | -- | 3 | 115 | -- | .25 | 11.01 | 312 | |||

| A | 3002-0013 | 150 | 1059 | 300 | 1 | -- | 3 | 115 | -- | .25 | 11.01 | 312 | |||

| A | 3002-0591, 3 | 150 | 1059 | 250 | -- | 1 | 2.5 | -- | 220 | .068 | 11.01 | 312 | |||

| A | 3002-002 | 138 | 975 | 200 | 1.5 | -- | 3 | 115 | -- | .25 | 11.01 | 312 | |||

| A | 3002-003 | 131 | 925 | 150 | 2 | -- | 3 | 115 | -- | .25 | 11.01 | 312 | |||

| A | 3002-0901 | 131 | 925 | 125 | -- | 2 | 2.5 | -- | 220 | .068 | 11.01 | 312 | |||

| A | 3002-005 | 110 | 777 | 75 | 4 | -- | 3 | 115 | -- | .25 | 11.01 | 312 | |||

| A | 3002-035 | 92 | 650 | 62.5 | -- | 4 | 2.5 | -- | 115 | .25 | 11.01 | 312 | |||

| A | 3002-0471 | 110 | 777 | 75 | 4 | -- | 3 | 24 | -- | 5.7 | 11.01 | 312 | |||

| A | 3002-0661 | 92 | 650 | 62.5 | -- | 4 | 2.5 | -- | 230 | .062 | 11.01 | 312 | |||

| A | 3002-0911 | 92 | 650 | 62.5 | -- | 4 | 2.5 | -- | 220 | .068 | 11.01 | 312 | |||

| A | 3002-007 | 74 | 523 | 50 | 6 | -- | 3 | 115 | -- | .25 | 11.01 | 312 | |||

| A | 3002-0741 | 74 | 523 | 50 | 6 | -- | 3 | 24 | -- | 5.7 | 11.01 | 312 | |||

| A | 3002-0781 | 61 | 431 | 41.67 | -- | 6 | 2.5 | -- | 230 | .062 | 11.01 | 312 | |||

| A | 3002-008 | 55 | 388 | 37.5 | 8 | -- | 3 | 115 | -- | .25 | 11.01 | 312 | |||

| A | 3002-009 | 44 | 311 | 30 | 10 | -- | 3 | 115 | -- | .25 | 11.01 | 312 | |||

| A | 3002-0491 | 37 | 258 | 25 | -- | 10 | 3 | -- | 220 | .068 | 11.01 | 312 | |||

| A | 3002-010 | 37 | 261 | 25 | 12 | -- | 3 | 115 | -- | .25 | 11.01 | 312 | |||

| A | 3002-0891 | 29 | 205 | 20 | 15 | -- | 3 | 24 | -- | 5.7 | 11.01 | 312 | |||

| A | 3002-013 | 24 | 170 | 15 | 20 | -- | 3 | 115 | -- | .25 | 11.01 | 312 | |||

| A | 3002-015 | 16 | 113 | 10 | 30 | -- | 3 | 115 | -- | .25 | 11.01 | 312 | |||

| A | 3002-016 | 8 | 57 | 5 | 60 | -- | 3 | 115 | -- | .25 | 11.01 | 312 | |||

| A | 3002-020 | 4 | 28 | 2.5 | 120 | -- | 3 | 115 | -- | .25 | 11.01 | 312 |

|

Notes: 1 Capacitor not supplied with motor. 2 Hi-Torque Rotor Construction. 3 Maximum Gear Train Loading. |